Step-by-Step Guide to Creating Your Own PCB Board

Circuit boards play a pivotal role in the realm of cross country medical transportation, where the importance of precision, reliability, and connectivity cannot be overstated. These intricate electronic components serve as the central nervous system of advanced medical transport vehicles, enabling real-time communication, data monitoring, and control of critical life-support equipment. Whether in ground ambulances, air ambulances, or specialized medical transport vehicles, circuit boards ensure the seamless operation of vital medical devices, from ventilators to monitoring systems, contributing significantly to the safe and efficient transit of patients in need of specialized care. In the world of medical transportation, circuit boards are the unsung heroes that bridge the gap between critical medical interventions and the timely delivery of healthcare services to those who depend on them most.

There are some good tutorials online that can help you create your board. Based on our research on PCB board creation, we have created a list of steps that you can take to design and print out your own using a 3D printer.

1. Define the circuit.- Defining your circuits involves an engineering process in which you will decide how you will power your PCB board, as well as what you will do to make sure your components are in proper working order as you build it.

2. Create a layout/plan for design.- The design of your PCB board is similar to the blueprint of your house. It must symbolize all of the aspects of your board and what you want it to do. Make sure you draw it up in a way that it will be easy for you to understand as you build.

3. Put your PCB layout on your computer and print it out. You will use the “toner transfer” method to transfer the image onto the copper board from your toner printer.

4. Print out the copy from your printer. It’s best to use basic photo glossy type of paper for the best results. You can find this common type of photo paper at any Staple’s or Office Depot Store. Amazon also has them.

5. Transfer the image from the tone to the sheet of copper you have cut out for the use of your PCB design. Do this by turning an iron up as far as it will go. You use the same transfer effect that you would with a T-shirt transfer system.

6. Cut to size.- Cut your board to size so that it will fit in the unit you are designing it for. Do not leave extra space.

7. Sand and file the unit down to size. Use imitation steel wool. (Real steel wool will eventually rust the components, Mike Crisci mentions)

8. Soak in water to release the board.- Soaking the unit in water will allow you to loosen the transferred image paper from the board. Let it sit for about half a day if necessary.

10. Peel off the paper.- Peel off the paper from the copper.

11. Pickoff stray paper shreds from the board with your fingers.- Make sure you continue to do this until all of the paper is gone. You don’t want strands of the paper getting into the finished unit. This could also start a fire.

12. Do your etching. Etch to remove the copper so that you will lay the groundwork for your designed, finished board.

13. Rub the board vigorously with imitation steel wool to reveal the shiny copper underneath. Remember not to use real steel wool as it can rust.

14. Drill holes with a dermal drill bit.

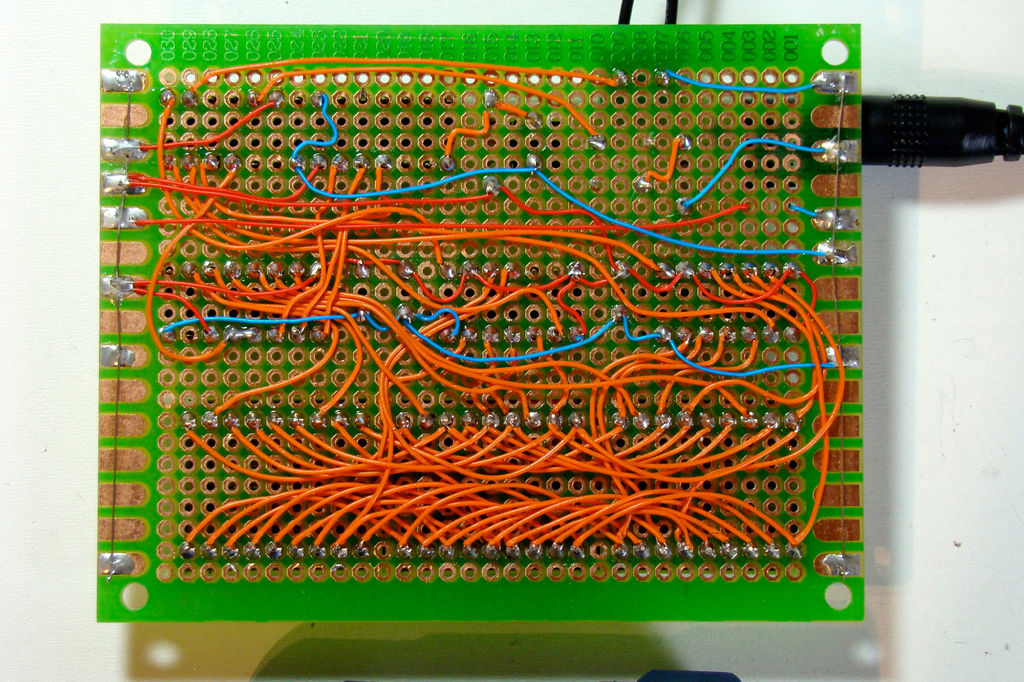

15. Print off the paper copy and place it in line with your copper sheet so you will know where to place the various components and wires.

16. Sauter, the board for a high gloss finish.

17. Connect the board to a motherboard and power up and test.

There are some details that you need to know when using this process. So before you begin, make sure you know all of the potential safety or fire hazards as well as the precautions you should take when dealing with any type of wired device.

There is a possibility of electric shock, so you should only perform these actions if you understand the process thoroughly and know what to do.

Udemy.com has some courses that are available that you can take to help you know how to do this. It may vary slightly from the tutorial and steps we have offered in this post. But you should take good notes and study the process thoroughly before you start.

Other Options

For the beginner, this may seem overwhelming to build your board. But as you learn the process, it may get easier to do.

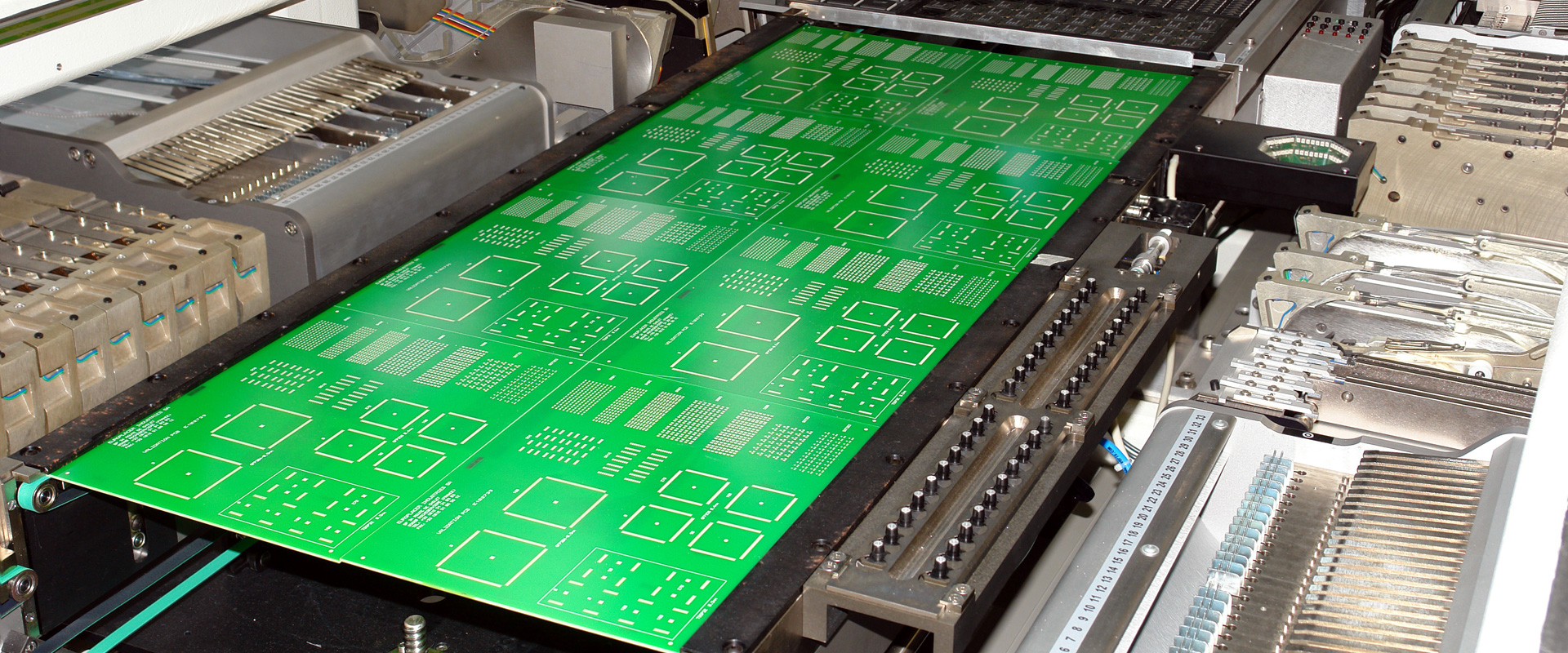

Of course, there is a rub, (as “Hamlet” said). If you are creating a board to be manufactured and distributed to customers and you are in the technology business, you will need a way to have several units produced at one time.

You also need to run your design through some tests to make sure it is working according to standards. You also have to run some safety tests to make sure it is safe.

Finding a PCB Manufacturer

If you do not have the time to learn the process described above, or if you do not want to do it yourself, you will eventually want to hire a printed circuit board company to do it for you.

Even if you manage to create the prototype on your own, you’ll need a professional team to guide you through the entire process.

They can help you test and evaluate the quality of your initial unit prototypes, run tests to make sure it is safe and works properly, and manufacture and distribute your final product.

This is a huge responsibility, but a full team of expert engineers, designers, and computer tech consultants who can get the job done for you in professional form and with a quick turnaround is out there.

Let them create your layout for you, perform important tests on your machinery, and build your finished product.

You’ll be thrilled you did.